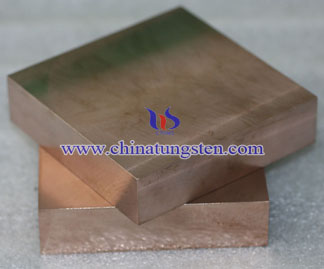

Copper Tungsten Background Information

Where to applycopper tungsten

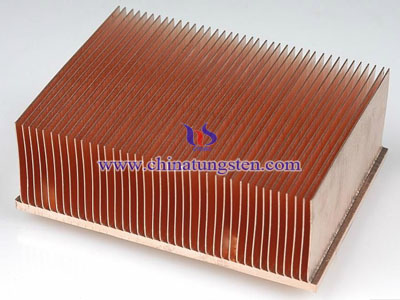

Cu-W alloys are used where the combination of high heat resistance, high electrical and/or thermal conductivity, and low thermal expansion are needed. Some of the applications are in electric resistance welding, as electrical contacts, and as heat sinks. As contact material the alloy is resistant to erosion by electric arc. W-Cu alloys are also used in electrodes for electrical discharge machining and electrochemical machining.

The CuW75 alloy, with 75% of tungsten, is widely used in chip carriers, substrates, flanges and frames for power semiconductor devices. The high thermal conductivity of copper together with the low thermal expansion of tungsten allows thermal expansion matching to silicon, gallium arsenide, and some ceramics. Other materials for these applications are CuMo alloy, AlSiC, and Dymalloy.

Alloy with 70-90% of tungsten is used in liners of some specialty shaped charges. The penetration is enhanced by factor 1.3 against copper for homogeneous steel target, as both the density and the break-up time are increased. Tungsten powder based shaped charge liners are especially suitable for oil well completion. Other ductile metals can be used as binder in place of copper as well. Graphite can be added as lubricant to the powder.

For different application should choice the different grade copper tungsten composition. The key factor is evaluating the hardness, electrical conductivity. Thread tapping is better use the Cu-W (72% by weight) tungsten composition. for some EDM electrode since it need to be machining after periods of using. The W-70% to 75% compositions is recommended.

The manufacturing process of copper tungsten alloy is to press the refractory (tungsten or tungsten carbide), sinter the pressed compact at a high temperature, and infiltrate with copper. All of this is done under very closely controlled conditions. The mechanical and physical properties of Tungsten copper alloy vary with composition. The thermal and electrical conductivity increased with the amount of copper, while the hardness, strength, and resistance to mechanical wear increase with the amount of tungsten or tungsten carbide. The application determines the material choice.