Copper Tungsten Different Classes

Copper tungsten class 10 (1W3, 5W3)

Class 10 material is recommended as facings or inserts for projection welding electrodes and flash and butt welding dies where high electrical conductivity is desirable and a degree of malleability is necessary.

Copper tungsten class 11 (10W3)

Class 11 (a harder material than Class 10) is recommended as facing inserts for flash and butt welding dies and general purpose projection welding electrodes. It may also be used as seam welder bearing inserts and facing for electro-forming or electro-forging, such as stainless steel.

Copper tungsten class 12 (30W3)

Class 12 material is specifically recommended for heavy duty projection welding electrodes and for die facings in electro-forming and electro-forging applications. It is suitable as die material for electrical upsetting of rivets and studs.

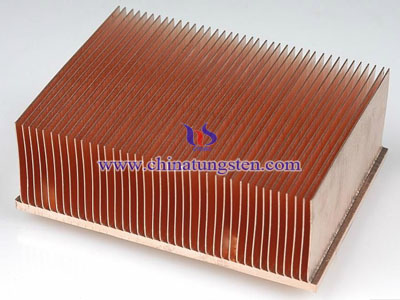

Copper tungsten from Chinatungsten owns the advantages as follows:

Highest thermal conductivity available for this material system

Isotropic thermal and mechanical properties

Tailored thermal expansions

Requires no expensive tooling

High precision components machined to customer print

Plating and metallization options available

Hermetic

Chinatungsten's manufacturing process begins with high purity tungsten powder that is compacted and sintered without adding lubricants, binders, or sintering aides. Sintered tungsten parts are then infiltrated with oxygen free high conductivity (OFHC) copper yielding a composite material with exceptional engineering properties. Our high purity sinter & infiltrate process produces a composite material with superior thermal conductivity, stability, and tailored thermal expansion.